Research Topics

SIRI Lab

System Integration

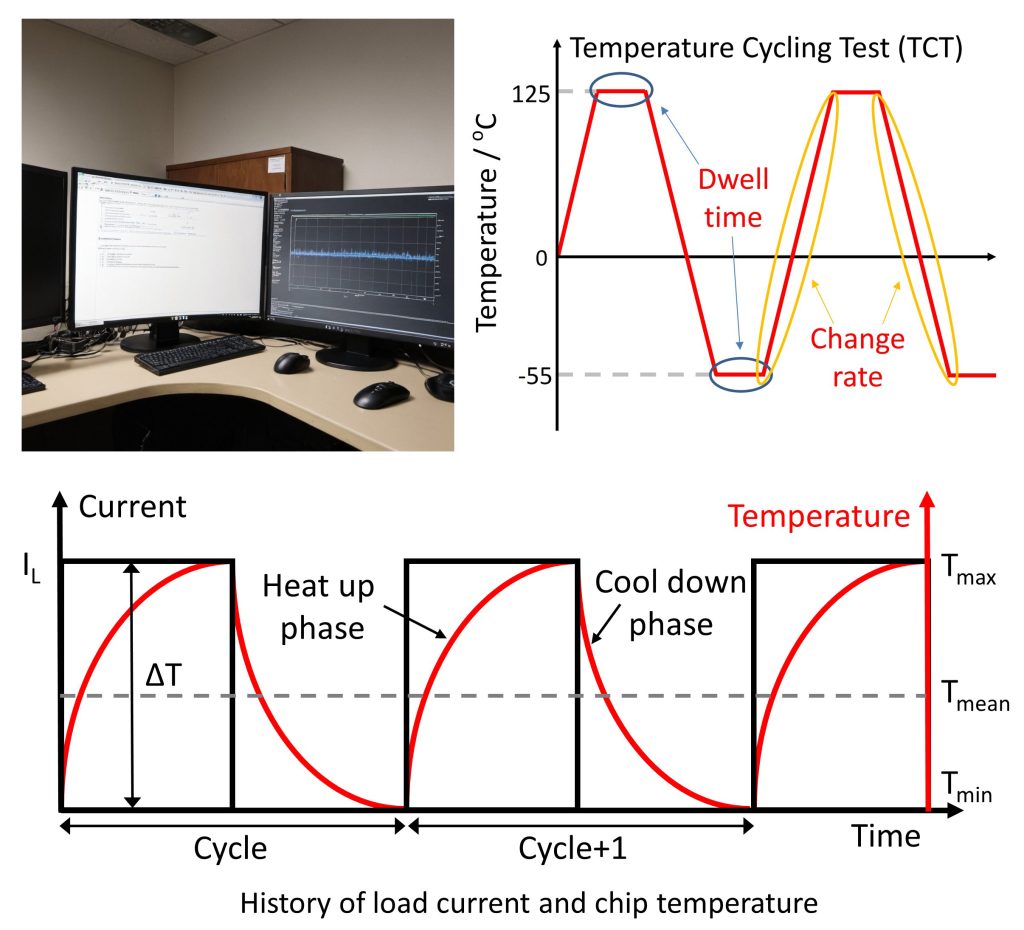

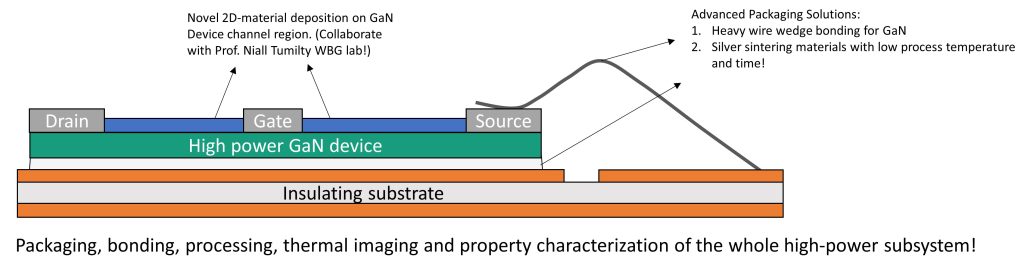

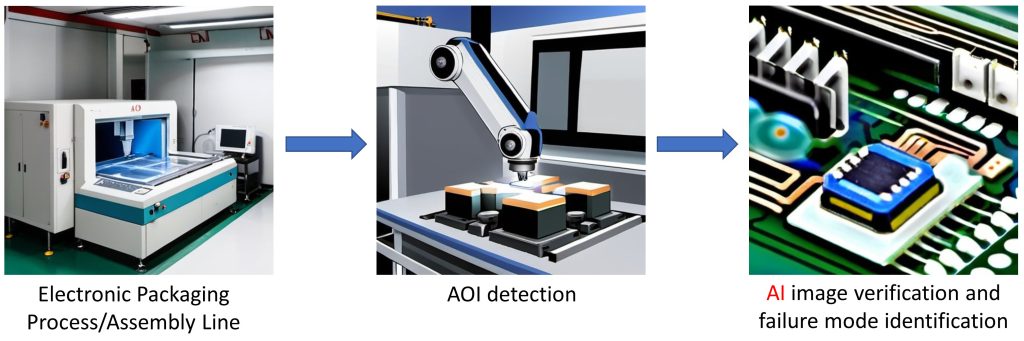

Packaging essentially requires the combination of electronic parts (transistors, connections, insulation) smoothly working in tandem and, if possible, enhancing the device function. This is why the buzzword heterogenous integration is at the core of advanced packaging. By finding the optimum method of integrating the parts, an improved modern device is made. In SIRI lab we use certain methods like active power cycling, heat management, and AI image verification to make the best semiconductor devices.